To view the price please login or register

Sign in

CRU.2R|X-Pack1 STANDARD PACK

Exclusive Package. Includes:[(CRU2rX-ih, BCN.B, DFI.01, DFI.02, SVI.01, CZI.01, BPI.01, BCI.01, HP90-M14/F12x15, HP-M12/F14x15, CZ-008541, CZ-007356)x1]

CZ-007356, HP90-M12/AF, SVI.01, BCI.01, CZI.01, BCN.B, DFI.01, DFI.02, BPI.01, CZ-008541

CRU.2R|X-Pack_2

'Exclusive CRDi Coding Package Includes: [(BC.01, DLC.03, DNC.04, RSP, 007121)x1]

BC.01, DLC.03, DNC.04, RSP

CRU.2R|X-Pack_VDO

Exclusive VDO Authorized Package Includes: [(VC.05, VDO.AUTH, CZ-007359, RSP, 007121)x1] [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007350]

VC.05, VDO.AUTH, CZ-007359, RSP

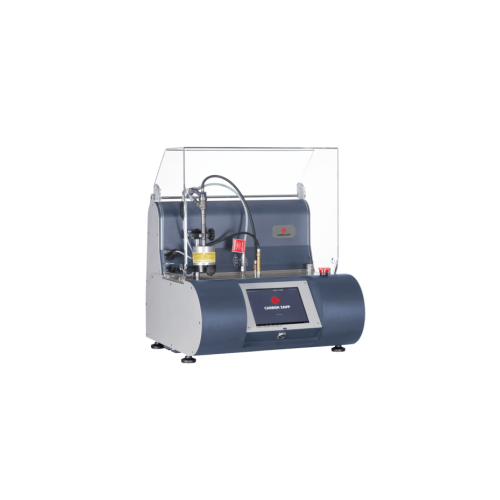

Service Station for All Makes Passenger Car, Light and Medium Duty CRDi systems

Overview of the New CRU.2r-X

Precise, repeatable and rapid Diesel Injectors Testing

Injector Testing&Coding

• 6-12 minutes testing and coding* time for injectors respectively

• CRi / CRiN injectors (All Brands and Types).

• Capable for all EU6 technologies such as VCC and NCC technology, iART, PCRS5,

Number of tested injectors 1 injector

Mains Supply

100-240 VAC / 1P / 50-60Hz (+/- 10%)

Compressed Air

6.5-10.0 bar / 400lt/min

Compressed Air Hose

<10m long / Internal Diameter >10mm

Rated Current / Fuse

5 A

Rated Power

300 Watt

Storage Temperature

-25 o C - +60o C

Operating Temperature

+5 o C - +45o C

Normal Operating Temperature

+10 o C - +40o C

Max Pressure (bar)

(20): 2200 / (30): 2500 / (40): 2800

Tightening Torque for High Pressure Connections

25 - 30 Nm

Clamping Diameter

17-32 mm

Test Oil Type / Capacity

ISO4113 / 3.5 lt

Test Oil Filter

2 microns

MACC Fluid Capacity

3.5 lt

MACC Fluid Filter

8 microns

Noise Emissions

<71.5dB(A)

Dimensions (W x D x H) / Weight

66 x 77 x 79 cm / 70kg

Additional options

Software Activations

BC.01

BOSCH CODING IMA/ISA (Solenoid & Piezo)

DLC.03

DELPHI CODING C2i AND C3i

DNC.04

DENSO CODING QR Including QR-32 (Requires RSP)

AZO.S

AZO SOFTWARE ANNUAL AFTER WARRANTY SUPPORT SUBSCRIPTION

VDO.AUTH

VDO AUTHORIZED ANNUAL LICENSE [ONLY FOR DRS PARTNERS]

VDO.RENEWAL

VDO AUTHORIZATION RENEWAL

CAT.1

CATERPILLAR CODING (CRDi & EUI) SW FOR AZO (Requires RSP)

DLC.04

DELPHI CODING C4i (Requires RSP)

Optional&Kits

CZ-007359

DIESEL CRi INJECTOR PRESSURIZED RETURN HOSE ADAPTERS KIT (PIR) [Includes 0.8 / 1.3 / 2 / 6 / 10 bar] [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007350]

CZ-007350

DIESEL CRi INJECTOR RETURN HOSE ADAPTERS KIT (BCL)

CZ-007356

MAIN BACK LEAK HOSE FOR INJECTOR RETURN ADAPTERS

RSP

STANDARD NOZZLE RESPONSE SENSOR ( 7-9mm ) FOR MTBr|X , ITB.1r|X , ITB.4r|X , GTB.4r|X , HTBr|X.(REQUIRES CZ-007101)

SPR.D

ILLIMINATED PRESSURISED SPRAY CHAMBER.(REQUIRES CZ-007102)

RSP.HD

HEAVY DUTY APPLICATION NOZZLE RESPONSE SENSOR AND DISCHARGE MEASUREMENT CELL FOR ALL MAKES. INCLUDED NOZZLE PIECE HDA.01 (7-9mm)(APPLICATIONS: CRIN 4.2, ACTROS, DD, XPI, etc…)

HDA.02

OPTIONAL FOR RSP-HD (11mm-MTU, etc...)[/pc]

HDA.03

OPTIONAL FOR RSP-HD (16mm- L'ORANGE, etc...)[/pc]

CZ4FK4-60C

FILTER ELEMENT ( METAL ) FOR INLINE FILTER 60 UM [/pc]

CZ-007121

MAIN RSP [sh] HARNESS FOR CRU.2R|X [SUCCESSOR: CRU2rX-sh.RSP]

EXCL.BCK_KIT1

EXCLUSIVE RETURN HOSES & FITTINGS KIT FOR CRDI (1 SLOT)

HD-F.01

High Pressure Filter for MTBR

HP90-M12/AF

90DEGREES ACCUMULATOR HP90-M12/AF

Diesel Injector Harness & Connectors

CZ-007107

ELECTRICAL CALIBRATED CABLE, INCLUDES HARDWARE & SOFTWARE COMPATIBILITY FOR CGL [RiD003793]

3P-VCC

CONNECTOR 3PIN FOR BOSCH CRS 3-25 WITH VCC SENSOR TECHNOLOGY [CRUR-MTBR-TBCR]

3P-VCC-KIT

KIT OF 4 CONNECTORS 3PIN FOR BOSCH CRS 3-25 WITH VCC SENSOR TECHNOLOGY [CRUR-MTBR-TBCR]

4P-NCA

CONNECTOR 4PIN FOR BOSCH PIEZO CRS 3-27 WITH NCA SENSOR TECHNOLOGY [CRUR-MTBR-TBCR] FOR BMW

4P-NCA-KIT

KIT OF 4 CONNECTORS 4PIN FOR BOSCH PIEZO CRS 3-27 WITH NCA SENSOR TECHNOLOGY [CRUR-MTBR-TBCR] FOR BMW

SVI.01

INJECTOR HARNESS CONNECTOR FOR SIEMENS

BCI.01

INJECTOR HARNESS CONNECTOR FOR BOSCH

CZI.01

INJECTOR HARNESS CONNECTOR GENERIC

BCN.B

INJECTOR HARNESS CONNECTOR FOR CRIN-M4

DFI.01

INJECTOR HARNESS CONNECTOR FOR DELPHI EURO 3/4

DFI.02

INJECTOR HARNESS CONNECTOR FOR DELPHI EURO 5

BPI.01

INJECTOR HARNESS CONNECTOR FOR BOSCH PIEZO

DEU.01

INJECTOR CONNECTOR INJECTOR HARNESS FOR DELPHI E1

DGXS-A

INJECTOR CONNECTOR DENSO 2PIN

DGXS-B

INJECTOR CONNECTOR FOR DENSO

DG2P-A

INJECTOR HARNESS CONNECTOR FOR SECOND GENERATION DENSO PIEZO

DG3P-A

INJECTOR HARNESS CONNECTOR DG3P-A FOR THIRD GENERATION DENSO PIEZO

iART-B

INJECTOR CONNECTOR DENSO 6PIN [REQUIRES PIRV.10-02]

iART-C

INJECTOR CONNECTOR DENSO 6PIN

UAC-01

GENERIC CABLE ADAPTER FOR CRIN / UNIT INJECTOR

PDE-P

INJECTOR HARNESS CONNECTOR PDE-P (REQUIRED FOR NTA 4170 OR CRS.10)

EXT.50

EXTENSION INJECTOR CABLE 50cm

CZ-007188

ELECTRICAL ADAPTER CABLE (Delphi E3

CZ-007189

ELECTRICAL ADAPTER CABLE (Ford Power Stroke)REQUIRES 2pcs [SUCCESSOR: ihM.02M-PWR]

CZ-007395

ELECTRICAL CALIBRATED CABLE [ NOT INCLUDED SW ] COMPATIBILITY FOR CGL [RiD003793]

PIDC

PIEZO / EURO 5 DELPHI EURO 5 INJ. CONNECTOR [/pc]

CZ-007192

ELECTRICAL ADAPTER CABLE (ISX-QSK)

CZ-008053

MAIN INJECTOR [ih] HARNESS FOR ITB.4R|X, GDU.4R|X, GTB4R|X, CRU.2/4R Slots #1/#2 & CRU.2R|X, HTBR|X DUAL COILS

CZ-008190

MAIN SENSOR HARNESS RSP/BIP FOR CRU.2R [SUCCESSOR: shM.02C-RB1]

CZ-008578

CRU.2r | X - Main injector [ih] harness [SUCCESSOR CRU2rX-ih]

CZ-008541

DISCHARGE/FLUSH ADAPTER w/BASE

DGxS-C

DENSO INJECTOR HARNESS CONNECTOR

CRIN Adapters for Common Rail Injectors

CRS.02

IVECO/ CUMMINS (KAMAZ, VW/FORD, DONGFENG DCEC) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.03

KHD/DEUTZ(BOSCH)[UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.04

RENAULT/MAZ/LIAZ/MZKT/TONAR/URAL/DONGFENG [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.05

FUSO TRUCKS (DENSO-6M60) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.06

FUSO TRUCKS (BOSCH-6M70) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.07

CUMMINS (4954927) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.09

DENSO OFF-HIGHWAY / JOHN DEERE

CRS.10

FORD 6.4L POWER STROKE (REQUIRES INJECTOR HARNESS CONNECTOR PDE-P) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.11

MAN/IH (INTERNATIONAL HARVESTER)/NAV-INTL (MWM) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.12

KHD/RENAULT DEUTZ(BOSCH)/RENAULT/FENDT DEUTZMAN (YAMZ)[UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.13

MTU-BOSCH (REQUIRES EL.CONNECTOR UAC.01) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.14

DENSO OFF-HIGHWAY / KOMATSU

CRS.17

MAN [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.18

IVECO [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.19

MECHANICAL INJECTOR REQUIRES UIP.01/02/03/04 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.21

DELPHI DAF INJECTOR (REQUIRES EL.CONNECTOR DEU-01) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.22

BOSCH KBEL162S93300BAR-790 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.23

CAT938H/CAT S2L106362752/ CAT 938H/ PERKINS 2645A734[UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.24

FOR ACTROS / BOSCH CRIN 4.2 (up to 2 Slots)

CRS.25

BOSCH MAN 044512024, 0445120044 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.26

DENSO OFF-HIGHWAY / JOHN DEERE

CRS.27

DENSO OFF-HIGHWAY / JOHN DEERE

CRS.28

SCANIA XPI INCLUDING DISCHARGE/FLUSH ADAPTER-CZ-003771 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.29

DENSO VOLVO CRIN 22490430 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.30

BOSCH CRIN 0445120063, 0445120051 , 0445120059 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.31

DENSO OFF-HIGHWAY / CATERPILLAR - PERKINS DENSO CRIN

CRS.32

DELPHI CRIN EURO 6 SMART INJECTOR A9361987/EP3770/11235/09771[UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.33

DELPHI CRIN EURO 6/5 SMART INJECTOR 073921083/1667208

CRS.34

DELPHI CRIN EURO 6 A0030179112/0708500669 [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.35

L’ORANGE (VTO - G266W488 CAL 934759) ADAPTER KIT INCLUDES HP CONNECTOR 12Mx1,5/23Fx1,5 w/ RELIEF

CRS.36

QSK Heavy Duty Injector [Bosch OE:Y431K05392/ Cummins:2867147 / Bosch:F00BJ00000] / Includes: 2 HP CONNECTORS [HP12/22C]

CRS.37

SIDE FEED ADAPTER FOR DAF (REQUIRES EL.CONNECTOR DEU-01) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.38

SIDE FEED ADAPTER CRS.38 FOR INJECTOR IVECO (EURO 6) [UP TO S/N #4419 REQUIRED TO BE ORDERED WITH CZ-007356]

CRS.39

ADAPTER CRS.39 FOR CATERPILAR COMMON RAIL INJECTOR (PN:4563493)

Calibration Oils & Fluids

D20L-ISO

CALIBRATION OIL ISO4113 FOR ALL DIESEL COMMON RAIL BENCHES w/ ELECTRONIC MEASUREMENT & TESTING UP TO 2800BAR [SUCCESSOR: B20L-AW2]

Y4L

ULTRASONIC CLEANING SOLVENT [4LT]

Y25L

ULTRASONIC CLEANING SOLVENT[25LT]

Trolley

CZ-002380

CARBON ZAPP TROLLEY V.1

CZ-002507

TROLLEY RACK BASE FOR CRP/CAMBOX ( MAX. 2 Pcs PER TROLLEY )

CZ-002587

TROLLEY DRAWER INSERT FOR CRP FLANGE ( MAX. 1 Pc PER TROLLEY )

CZ-002765

TROLLEY SIDE RACK FOR HOSES/WIRES ( MAX.2 PER TROLLEY )

Ultrasonic Baths

UB-15S

HEAT CONTROL/ 42KHZ / 1.75L [FOR R & X UNITS REQUIRES EXT.50]

UB-15E/110V

SWEEP TECHNOLOGY 31-42KHZ/DEGAS/HEAT/1.5L/ 51x137x100mm-110V (ELMA) [FOR R & X UNITS REQUIRES EXT.50]

UB-15E/220V

SWEEP TECHNOLOGY 31-42KHZ/DEGAS/HEAT/1.5L/ 51x137x100mm-220V (ELMA) [FOR R & X UNITS REQUIRES EXT.50]

UB-30E

ULTRASONIC BATH STANDARD: HEAT CONTROL/ 2,75L/ 240x137x100mm (ELMA)

UB-60E

ULTRASONIC BATH STANDARD: HEAT CONTROL/ 5,75L/ 300x151x150mm (ELMA)

UB-120E

ULTRASONIC BATH STANDARD: HEAT CONTROL/12,75L/ 300x240x200mm (ELMA) [INCLUDED COVER & BASKET]

UB-120

ULTRASONIC BATH STANDARD: HEAT CONTROL/12,75L/ 300x240x200mm (ELMA) [WITHOUT COVER & BASKET]

UB-450E

HEAT CONTROL/ 45L/ 500x300x300mm (ELMA)

To view equipment prices please login or register.

By continuing browsing this website, you accept the use of cookies or other tracers for statistics of visits to optimize the functionality of the site.

OK